Details You Can’t Afford to Miss When Designing Hardware for Your Startup

If you think starting a new business that produces hardware-based products is difficult, think again. There are reasons why we have been seeing an increasing number of new hardware startups these past couple of years. Aside from the Internet of Things (IoT) becoming a hotter trend, low entry barriers also make the hardware startup landscape easier to penetrate.

Designing a hardware-based product is an exciting process on its own. However, you still have to design the hardware that you will market as a product with care. There are some important details you cannot afford to miss, and we are going to review them in this article.

Efficient Schematics Design

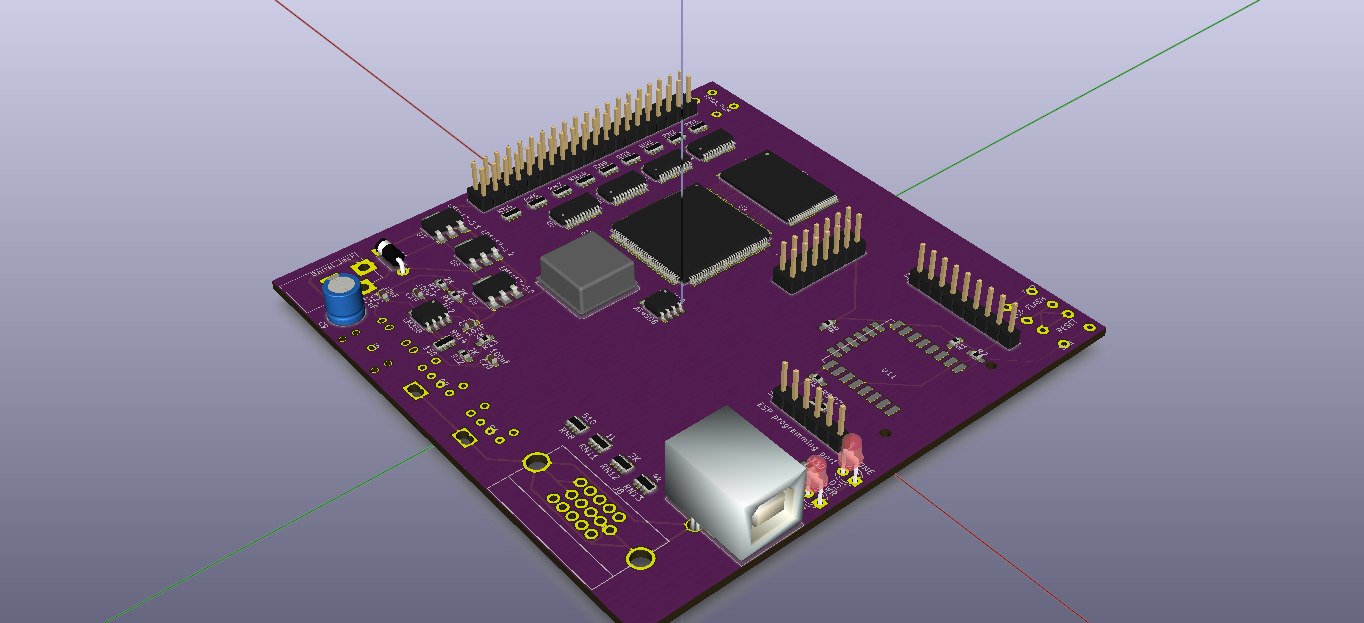

Designing a board for your product is one of the first steps you need to do when bringing your product idea to life. Unfortunately, a lot of new startups rushed through this process, and the majority of them ended up with products that weren’t always easy to improve.

Getting the schematics design right is important. You want to make sure that the board layout allows for easy iterations. You also want to make sure that you can continue improving the product and making new versions of it without having to design everything from scratch.

Following the essential design rules when creating schematics is important. You want to make sure that all wires, busses, and components are documented properly.You also want to add details about parameters and the overall routing of the board.

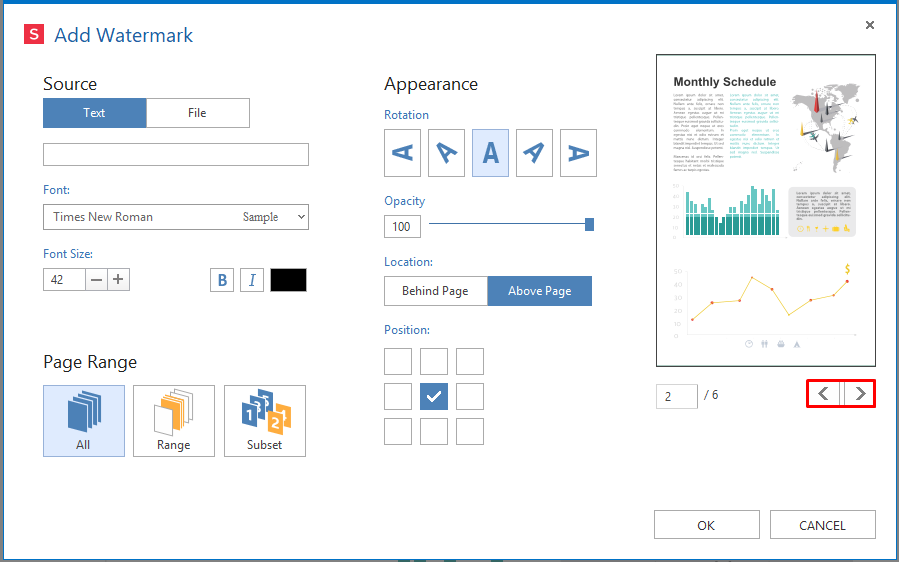

This is where a good schematic capture software like Altium Designer Schematic Capture comes in handy. With its modern schematic capture editor, Altium Designer lets you maintain the whole design process and details associated with it using one comprehensive tool.

Part Clearance and Body Design

Designing the board for efficiency is important, but it is also necessary to make sure that the board can be manufactured with ease. This means making sure that all parts used on the board as well as supporting components that make up for the rest of the product fit together perfectly.

Body design and part clearance are two details that are best considered early in the design process. You can make manufacturing your product an easy task to complete when these details are figured out beforehand. Of course, the same schematic design tool – Altium Designer – can also be used to check parts clearance and figure out other details about the board.

The flexibility of modern board design software means you can work towards making an efficient board for your product while ensuring easy manufacturing. You can even source parts and get details about components used in the manufacturing process while still in the design phase.

Getting Started

There are other details that you need to get right in order to create a high-quality product. That said, there are also more resources to help you get to that level of quality without neglecting important details. With everything else – including actually manufacturing the board and product – also at your fingertips, all you need to do now is begin the process of turning your product idea into an actual, tangible hardware.